Hydrogen Energy

With Korea's top LNG business capabilities and infrastructure,

SK E&S will complete the hydrogen value chain including the production, distribution,

and consumption of clean hydrogen to become a global leader in the hydrogen energy field.

SK E&S will complete the hydrogen value chain including the production, distribution,

and consumption of clean hydrogen to become a global leader in the hydrogen energy field.

-

Entering the hydrogen market early on

Entering the hydrogen market early on

by utilizing LNG infrastructure -

Produce blue hydrogen using CCS

Produce blue hydrogen using CCS

technology and owned waste gas fields -

Entering the Asian hydrogen market

Entering the Asian hydrogen market

through cooperation with the US Plug Power

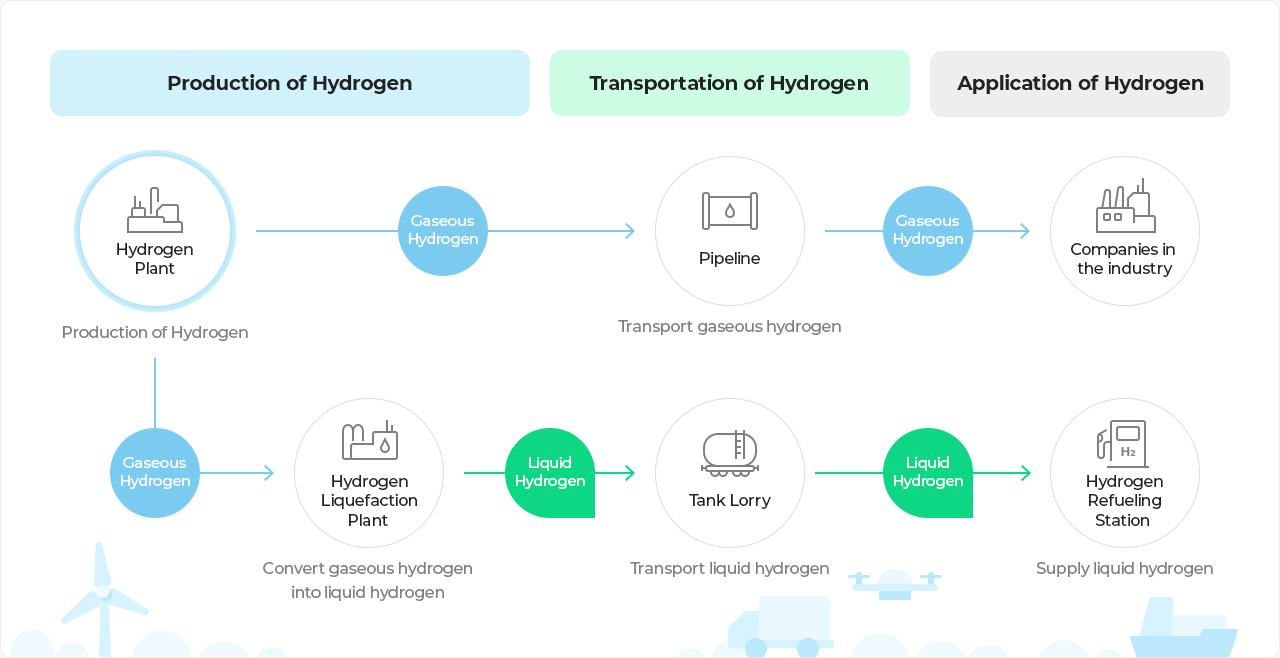

We are building a hydrogen value chain infrastructure

from the production of hydrogen energy to distribution and consumption.

- Production of Hydrogen Hydrogen Plant Hydrogen Liquefaction Plant

- Transportation of Hydrogen Pipeline Tank Lorry

- Application of Hydrogen Hydrogen Fuel Cell Hydrogen Refueling Station

We are executing a concrete strategy in phase

to create a hydrogen ecosystem.

Project Phase 1

-

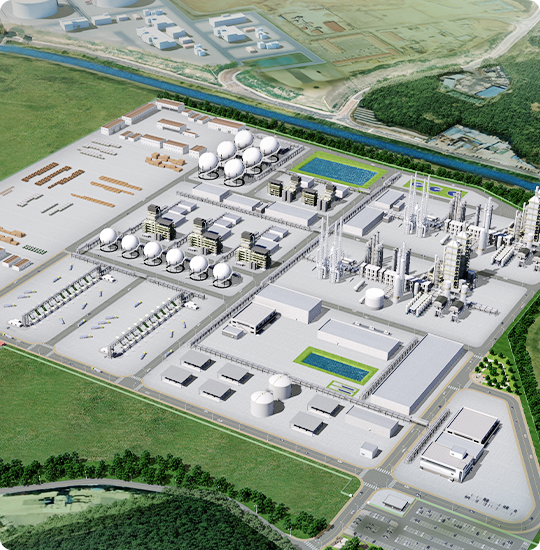

Build the world's largest liquefaction plant

SK E&S is building the world's largest hydrogen liquefaction plant on 15,000 pyeong of land inside SK Incheon Petrochemical Plant. Since it is the only hydrogen liquefied plant located in the metropolitan area in Korea, it is expected to be able to transport and supply economically to the metropolitan area, which is the main demand. -

Aerial view of Incheon Hydrogen Liquefaction Plant

Aerial view of Incheon Hydrogen Liquefaction Plant -

-

Supply of 30,000 tons of

liquid hydrogenSK E&S will liquefy byproduct hydrogen produced by SK Incheon Petrochemical and produce 30,000 tons of liquefied hydrogen in all parts of the country, including the Seoul metropolitan area, from 2024. -

Storing and transporting hydrogen

safely and efficientlyWhen gaseous hydrogen is cooled to -253°C and liquefied, the mass is down to 1/800, which makes storage and transportation of hydrogen much easier, more efficient and more economically feasible. -

Plug Power Inc. Liquefaction tank lorries.

Plug Power Inc. Liquefaction tank lorries.

Project Phase 2

-

Production of 250,000 tons of

clean blue hydrogen per yearSK E&S plans to produce 250,000 tons of clean blue hydrogen from natural gas per year. Clean blue hydrogen refers to the hydrogen that captures and removes the carbon dioxide generated when hydrogen is produced. -

-

Aerial view of Boryeong Blue Hydrogen Plant

Aerial view of Boryeong Blue Hydrogen Plant -

Using LNG value chain

to produce clean blue hydrogenClean hydrogen plant is near Boryong LNG Terminal created jointly by SK E&S and GS. Natural gas is the source of clean hydrogen and is supplied through LNG value chain infrastructure that SK E&S has built. -

Entry into the Asian market by building a joint venture with Plug Power, an American firm

Through the joint venture, we will build a "Giga Factory & R&D Center" in the Seoul metropolitan area and mass-produce key facilities of the hydrogen business such as hydrogen fuel cells and water electrolysis facilities to enter the Asian hydrogen market. -

Plug Power Inc. Hydrogen fuel cell power packs

Plug Power Inc. Hydrogen fuel cell power packs -

-

Completion of green

hydrogen value chains by producing green hydrogenIn the long run, we will also actively promote green hydrogen production projects using renewable energy such as solar and wind power to complete an eco-friendly hydrogen value chain that does not emit carbon dioxide at all.